Technical information on Intelligent solder paste cabinet

2021-11-04 10:50:20 来源:普玛仕

In today's competitive manufacturing landscape, intelligent solder paste management cabinets emerge as a game - changer, offering significant value, especially in cost - cutting and efficiency enhancement.

Labor Cost ReductionThese cabinets automate the entire solder paste lifecycle—storage, tempering, stirring, and dispensing. By eliminating manual intervention, they reduce quality issues caused by human error, directly slashing labor costs. Fewer personnel are needed to oversee operations, translating to immediate savings.

Quality Control and Waste MinimizationEquipped with safety stock features and expiration warnings, the cabinets ensure solder paste freshness. Their strict first - in, first - out (FIFO) rule, with priority for re - stored paste, minimizes waste. A robust traceability system allows for quick quality checks and issue resolution, safeguarding production integrity.

MES Integration for Brand BoostIntegration with the Manufacturing Execution System (MES) enables real - time data exchange between cabinets, equipment, and the MES. This seamless connection supports operation monitoring and control. Using such advanced equipment not only optimizes production but also elevates a company's technological image, enhancing market competitiveness.

Intelligent Control FeaturesUser - Friendly SecurityThe cabinets' management system uses biometric tech like facial and fingerprint recognition for fast, secure logins. This protects data and simplifies access, while also providing a personalized user experience.

Smart Solder Paste HandlingThe system automatically records key solder paste details—expiration, batch, consumption, and weight—upon storage. Real - time monitoring flags issues like approaching expiration or weight anomalies. At dispatch, it generates detailed labels, creating a transparent material flow and a complete data trace for better supply chain management.

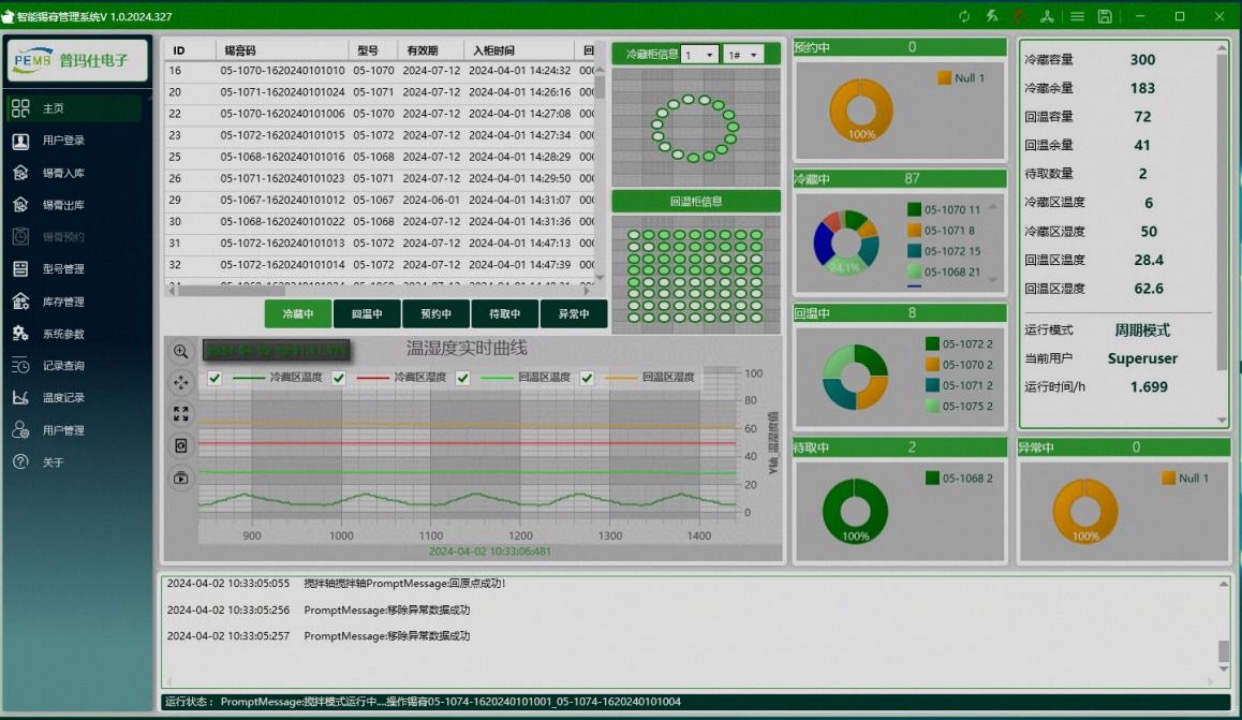

Simple Software OperationThe intuitive software interface features a clean layout and easy - to - use functions. Employees can quickly master it, reducing training time and costs. A one - click query accesses historical temperature and humidity data, helping maintain an ideal production environment.

Multilingual Global AdaptabilityWith support for major languages such as Chinese, English, and German, the system caters to a global workforce. Users can switch languages for a localized experience, making the cabinets suitable for international operations.

Intelligent solder paste management cabinets are redefining manufacturing standards. Their blend of cost - effectiveness, quality control, and smart features positions them as essential tools for modern industrial growth.

System Advantages

Optimized Robotic Arm System: Our meticulously designed robotic arm system is both simple and robust, combining high - efficiency operation with easy maintenance. The layout of the cold storage and tempering areas follows process flow and ergonomic principles, enabling the robot to take the shortest path during tasks, reducing idle movements and significantly enhancing work efficiency and system stability. The equipment arrangement in the cold storage and tempering zones ensures continuous workflow without interference, facilitating smooth material flow and reducing energy consumption.

High - Precision Servo - Driven Stirring: The robotic arm adopts full - servo control technology. Compared with traditional stepper motors, servo motors offer faster speed response and higher precision. This allows the stirring mechanism to maintain excellent mixing uniformity even at a maximum speed of 1000 rpm. The full - servo design of the stirring mechanism not only improves mixing efficiency but also ensures precise control during the process, meeting diverse process requirements.

Innovative Cold Storage Design: The cold storage area features an optimized tower - type turntable design. Each storage slot is equipped with a compact automatic door, saving valuable floor space while maximizing storage capacity. This compact design significantly increases material storage density per unit area, meeting the strict space - utilization requirements of modern factories.

Advanced Intelligent Control: The system pre - plans material pick - and - place positions during idle periods, enabling the robot to transfer materials quickly and accurately, reducing door - opening time and minimizing temperature loss to maintain a stable cold storage environment. Integrated with high - precision encoders to form a closed - loop control system, and using fuzzy adaptive control algorithms, the robot can self - adjust and position precisely in real - time, eliminating the need for cumbersome manual compensation. This greatly enhances the system's automation level and operation accuracy.

Powerful Control Architecture: The robotic arm system is built with up to six high - performance servo systems and high - precision motion control cards, forming an efficient and stable closed - loop control system. Compared with traditional PLC solutions, this system has significant advantages in data - processing capabilities, response speed, and scalability. It can handle larger data streams, manage more complex motion control tasks, and is easily upgradable and integrable with new functional modules, providing strong support for future production line upgrades and expansions. This design not only ensures efficient and stable current operations but also reserves ample technical room for future process improvements and capacity enhancements.

Internet of Things (IoT) Capabilities

Seamless Connectivity and Management: The system supports the Internet of Things, enabling real - time remote monitoring of all device statuses when connected to the external network. It accurately statistics and generates device operation reports, and allows users to make remote reservation operations for efficient device management and pre - scheduling. In an internal network environment, the system can be seamlessly integrated with the Manufacturing Execution System (MES), enabling accurate binding of work orders to devices, MES - based reservation functions, and detailed status recording and tracking management, ensuring transparency and controllability of the production process.

Multi - Platform Accessibility: To meet the needs of different user groups and work scenarios, the system offers cross - platform multi - terminal interface sharing. It is compatible with mainstream operating systems, including Android, iOS, and Windows, and is equipped with a Web application programming interface. This allows users to access and control the system conveniently via a browser from anywhere, enabling seamless device monitoring and production management at any time and place.